Introduction

The fracture of denture causes inconvenience to the patient & embarrassment to the dentist. Denture fracture may occur either inside the mouth during function, primarily because of deflective occlusal forces or resin fatigue or outside the mouth through impact if the denture is dropped[1]. Hence there is a need for improvement in the fracture resistance of polymethylmethacrylate. Denture base materials have always been a matter of research in the field of dental materials. Various previous studies[2],[3],[4] were done on mechanical as well as physical properties of denture base materials. In recent times, many approaches have been used to strengthen the polymethylmetha crylate denture base resin, among these one approach is reinforcement with different types of fibers. A major difficulity with these fibers is bonding with denture base resin is difficult[5]. A search for alternative material has led to the introduction of nylon based denture base material. To date, no research has assessed the lately developed nylon based flexible resin system for denture base construction. Lucitone FRS is a flexible and monomer-free thermoplastic dental polymer[6].

Flexural failure of denture base materials is considered the primary mode of clinical study[7]. Zappini et al[8] stated that to evaluate the resistance of denture base resins against fracture, fracture toughness tests as well as impact strength should be performed.

Due to increased concern for quality control and to obtain assures results repeatedly, the evaluation of such newly introduced and currently available products is imperative[1]. This study is one such effort to evaluate and compare the properties related to the fracture resistance i.e. flexural and impact strength of a nylon denture base material to other polymethylmethacrylate denture base material.

Materials & Methods

Three different denture base materials were used in this study (i.e. co-polyamide nylon denture base resin Lucitone FRS Dentsply Pvt. Ltd., high impact polymethylmethacrylate denture base resin Trevalon HI Dentsply Pvt. Ltd. and conventional polymethylmethacrylate- DPI Heat Cure Dental Product of India Pvt. Ltd.) for evaluation and comparison of flexural strength and impact strength. The methodology has been described as:

Preparation Of Metal Strips

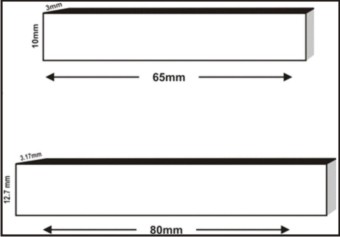

Stainless steel metal strips for flexural strength of dimensions 65 x 10 x 3 mm (Fig.1 a) and for impact strength samples dimensions 80 x 12.7 x 3.17 mm (Fig.1 b) were fabricated from a private engineering works according to ADA specification no. 12[9] and ASTM D-256[10] respectively. These metal strips were used to prepare the samples from each of the three materials.

| Fig.1 : A Dimensions Of Metal Strip (Ada Specification No.12) B Dimensions Of Metal Strip (Astm D-256)

|

Preparation Of Samples

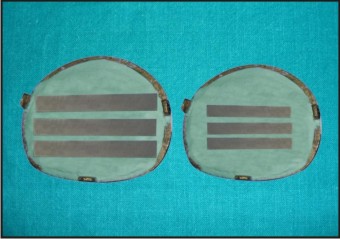

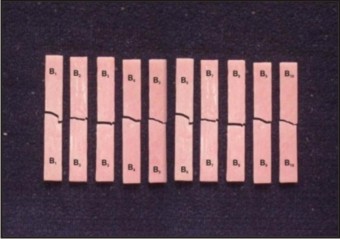

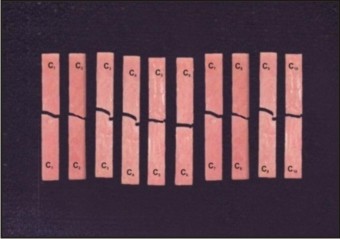

Total of 60 resin samples were made from three different materials selected for this study i.e. Lucitone FRS (Fig.2,3,4,5) (Group A), Trevalon HI (Group B) and DPI Heat Cure (Group C) (Fig.6,7). 20 samples were made from each group, which were further divided into 2 subgroups each , 10 samples for flexural strength(f) and 10 for impact strength(i). Sample size is chosen using a target for the power of a statistical test to be applied once the sample is collected. So, all the groups and subgroups were represented as Af, Ai, Bf, Bi, Cf, Ci .All the samples were immersed in distilled water in three different jars at 37°C in an incubator for 1 week before testing[1]. This was done to simulate the oral conditions.

| Fig.2 : Fabrication Of Lucitone Frs Samples: (A)Impact Strength (B) Flexural Strength

|

| Fig.3 : After Dewaxing : (A)Impact Strength & (B) Flexural Strength

|

| Fig.4 : Cartridge Sleeve Preheated In Success Cartridge Furnance

|

| Fig.5 : Cartridge Containing Molten Lucitone Frs Placed On To The Success Injection Unit

|

| Fig.6 : Flasking Of Metal Strips For Fabrication Of Samples: Impact Strength (Left Side) And Flexural Strength (Right Side)

|

| Fig.7 : After Dewaxing (A) Flexural Strength And (B) Impact Strength

|

• Testing of samples

• Testing of samples for flexural strength

• Testing of samples for impact strength

• Testing of samples for flexural strength- Flexural strength is measured in terms of stress. Flexural strength of samples was tested on Instron universal testing machine (model LR 100 K, LLOYDS, UK) at a cross head speed of 2 mm/min and span length of 50 mm[11]. The load was applied centrally on the bar sample until fracture occurred. The load and corresponding deflection were recorded for each sample. Load deflection curve (stress-strain curve) was observed for each sample, showing the amount of stress applied on the material which led to strain

Flexural strength for each sample was calculated using the formula - Flexural strength (Mpa) = Where, P=peak load, l =span length, b=sample width, d=sample thickness.

All the polymethyl methacrylate samples fractured. (Fig.8,9). For nylon samples it was decided to record the maximum load (P) once the load deflection curve became constant. This was done because it was observed from pilot study that the nylon samples (Lucitone FRS) did not fracture but deflected beyond the capacity of the machine (Fig.10). For materials that deformed significantly but did not break, flexural yield strength was calculated[6]. Flexural yield strength is the stress at which material strain changes from elastic deformation to plastic deformation, causing it to deform permanently.

| Fig.8 : Fractured Samples After Testing For Flexural Strength: ( Trevalonhi )

|

| Fig.9 : Fractured Samples After Testing For Flexural Strength: ( Dpi Heat Cure )

|

| Fig.10 : Deflected Lucitone Frs Samples

|

Testing of samples for impact strength – Impact strength of samples were tested on Izod Digital Impact Tester (ATS Faar Italy) with accuracy of 0.01 J. For Impact strength a ‘V’ shaped notch to a depth of 2.5 mm (according to ASTM standard D618)[10] was made in the centre on a lateral margin across the long axis of the samples for impact strength. The notching of samples were done with the help of NOTCH VIS (CEAST) Machine. Before notching the width of sample was 12.7 mm but after making a notch the width remained 10.2 mm for each sample. The notch prepared in samples simulated the notches present in denture base in frenal areas. The notches and scratches are stress concentrated areas which may reduce the strength of denture. The presence of a notch also ensured that the test specimens break at the same point during testing[12].

The samples were clamped vertically at one end in such a way that half of the length remained outse with a notch. The pendulum of 2J was released towards the side of the notch of the sample[13]. It was observed that the sample was broken and the absorbed energy by the each sample was noted.

The impact strength was calculated using the formula- Impact Strength (KJ/m2) = Where, E = energy absorbed by the sample ; b = sample width ; d = sample thickness

Result

Sub group Af (Lucitone FRS) samples did not fracture during the flexural strength test and deflected beyond the capacity of testing machine. Hence for sub group Af samples, the load (i.e. value of P) at which the load deflection curve reached the maximum and became constant were recorded and were considered as flexural yield strength[6]. For sub group Bf (Trevalon HI), and sub group Cf (DPI Heat Cure) samples flexural strength was calculated. An analysis of difference in flexural strengths of different groups was carried out using one-way analysis of variance (ANOVA) test. (Table - I)Then, Bonferroni Post Hoc test of significance for flexural strength differences among the means of different groups was carried out. This revealed that all the 3 groups were highly significantly different from each other (Table - II). The software used for statistical analysis was SPSS Processor version 15.

| Table I : Analysis Of Difference In Flexural Strengths Of Different Subgroups Using One-way Analysis Of Variance (Anova) Test

|

| Table II : Bonferroni Post Hoc Test Of Significance For Flexural Strength Differences Among The Means Of Different Groups

|

Trevalon HI (Group B) showed the maximum mean value of flexural strength 143.61 Mpa. It showed the maximum peak load value of 17.67 Kg. i.e. maximum stress required to break the samples. DPI Heat Cure (Group C) showed the second highest mean value of flexural strength 130.15 Mpa with peak load value of 15.91 Kg whereas the mean value of flexural yield strength of Lucitone FRS was 114.15 Mpa with peak load value of 13.96 Kg (Graph-1). The low flexural strength exhibited by Lucitone FRS (Group A) means that it is less rigid than conventional polymethylmethacrylate resins. Lucitone FRS samples did not break because they reached above their proportional limit.

| Graph -1 : Comparison Of Flexural Strength Among Three Different Groups

|

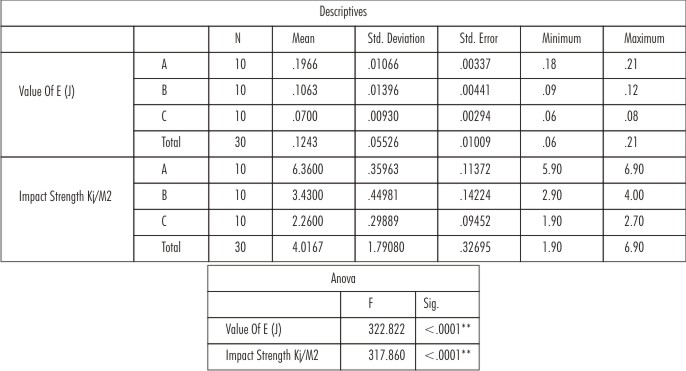

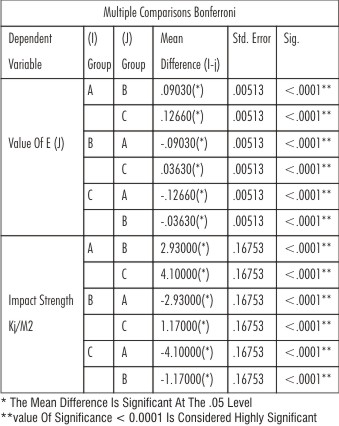

An analysis of difference in impact strengths of different subgroups (Ai, Bi, Ci ) was carried out using one-way analysis of variance (ANOVA) test (Table - III). Then, Bonferroni Post Hoc test of significance for impact strength differences among the means of different groups was carried out. This revealed that all the 3 groups were highly significantly different from each other (Table - IV).

| Table III : Analysis Of Difference In Impact Strengths Of Different Subgroups Using One-way Analysis Of Variance (Anova) Test

|

| Table IV : Bonferroni Post Hoc Test Of Significance For Impact Strength Differences Among The Means Of Different Groups

|

Lucitone FRS (Group A) showed the highest impact strength of 6.36 KJ/m2. The flexibility of Lucitone FRS coupled with its strength (impact) enables it to resist all normal attempts at fracture. The samples of Lucitone FRS showed the maximum energy absorbed i.e. 0.196 J to break the samples. Trevalon HI (Group B) showed the second highest impact strength of 3.43KJ/m2 as less energy was absorbed i.e. 0.106 J in breaking these samples as compared to Lucitone FRS. Whereas DPI Heat Cure (Group C) on application of a sudden force showed impact strength of 2.26 KJ/m2 with least energy absorbed i.e 0.070 J. (Graph-2).

| Graph -2 : Comparison Of Impact Strength Among Three Different Groups

|

Discussion

Problems encountered when fabricating a partial denture prosthesis using polymethylmethacrylate resin are that as the material is rigid, the undercuts present around the teeth and the tissues have to be blocked out so that insertion and removal of the prosthesis can be done without interferences and damage to the tissues. This block out of the undercuts has undesirable effects like presence of dead space, poor esthetics, food entrapment and soft tissue proliferation. Further, in these prosthesis the use of wrought wire metal clasps to enhance retention becomes vital thus compromising esthetics. Hence attempts to overcome the limitations of polymethylmetha crylate have taken researchers through many avenues. Radford; Radford & Braden[14] did the chemical modification of polymethyl methacrylate resin through the incorporation of rubber in the form of butadiene styrene in improving the impact strength but with limited success

Jagger DC., Harrison A , Jandt K.D.[15] studied the reinforcements of denture base material and gave different reviews of attempts to improve the mechanical properties of polymethyl methacrylate denture base. It showed that rubber modified acrylic-polymer had high impact strength.

High impact denture base resin (Trevalon HI) is fiber reinforced resin. Trevalon HI is a micro-dispersed rubber - phase polymer, in which methyl methacrylate and butadiene styrene are co-polymerized in an emulsion with a second coating of methyl methacrylate being added to cover the bead. These beads are mixed with monomer to form the dough that is packed into the dental flask[16]. These high impact resins are well suited for the patients with heavy masticatory forces and also for complete/partial conventional dentures. Impact strength may be defined as the energy required for fracturing a material under an impact force. The term impact is used to describe the reaction of a stationary object to a collision with a moving object.

Flexible denture base material eg. Lucitone FRS is thermoplastic co-polyamide nylon polymer. Nylon is a generic name of certain type of thermoplastic polymers belonging to the class known as polyamides. Polyamide molecules contain the amide group CONH, spaced at intervals in a carbon chain. Nylon is a crystalline polymer whereas polymethylmethacrylate is amorphous. Thus in solid nylon there is more or less ordered parallel packing of the long chain molecules which is due to the strong attractive forces between the chains. This crystallinity accounts for lack of solubility in solvents, high heat resistance and high strength coupled with ductility[17]. This difference in internal molecular structure contributes to the outstanding features of toughness, low density, abrasion resistance, high melting point and resistance to chemical attack. They are well suited in certain type of partially edentulous conditions i.e. tooth and tissue supported prosthesis (long bounded saddle) as the tissue-borne saddles will move relative to the tooth-borne ones during mastication[18]. This flexibility of nylon makes it possible to use simpler designs of the prosthesis and can be the material of choice in anterior teeth replacement because the need to block out the undercuts are not required and hence deliver a prosthesis that is esthetically superior[19].

Flexural strength is defined as a material’s ability to resist deformation under load. The flexural strength represents the highest stress experienced within the material at its modulus of rupture. The low flexural strength exhibited by Lucitone FRS (Group A) means that it is less rigid than conventional polymethylmethacrylate resins. Lucitone FRS samples did not break because the Lucitone FRS reached above to its proportional limit. That is why it is indicated in repeated denture fracture cases and in certain clinical situations, which allows it to engage certain degree of undercuts for retention without these undercuts being blocked.

Conclusion

Within the limitations of this study, it was concluded that Lucitone FRS is more flexible than other two materials as Lucitone FRS samples did not break during testing of flexural strength. They flexed beyond the capacity of the machine and slipped from the supporting wedges of the machine. Whereas for impact strength testing, this material showed highest value as maximum energy was required in breaking this material than the other two materials. So, Lucitone FRS material exhibits flexibility, high impact strength and excellent retention. It can be used in removable partial dentures where undercuts are present and also in situations where repeated denture fractures have occurred. Another advantage of this material is that it is esthetically acceptable as this material merges itself with the oral tissues and is virtually invisible as there is no need of metal clasps in the denture. This material has certain limitations that it stains easily and show high water sorption. The manufacturers recommend a design that does not incorporate rests to provide vertical support since the inherent flexibility of the nylon material may fail to effectively transfer the forces from the prosthesis to the abutment. This is an inherent disadvantage of Lucitone FRS prosthesis as the prosthesis derives only retention from the abutment tooth but no support from it. Other problems faced with this material are that repair or relining is infeasible, high cost and expensive equipments.

Trevalon HI showed the maximum flexural strength. It means that this material can bear heavy masticatory load easily and leading to better chewing efficiency. This material is also recommended in V-shaped palate and broad arches. DPI heat cure showed least flexural and impact strength values. So, strength wise DPI heat cure stands at third place than rest of the two materials. This material can be used in conventional conditions and is cost effective than rest of the two materials. Though Lucitone FRS is gaining attention but Trevalon HI is an acceptable material for both partial and complete dentures as this material can bear the heavy masticatory forces. Secondly, its colour stability is better than the other two materials.

The mechanical behavior of a denture depends not only on the strength of the material but also on the design, construction and conditions of loading. Factors like different powder/liquid ratio, homogenous co polymer beads, differences in water uptake may also affect the mechanical properties. Therefore, the resin should possess adequate strength and resilience as well as resistance to biting or chewing forces, impact forces that occur in the oral cavity. The laboratory test results for any resin are not necessarily equivalent to clinical findings, even though efforts are made to simulate the clinical conditions in laboratory experiments. The data obtained in this study for flexural strength and impact strength pertain to the conditions in which they are tested but with any changes in the materials and methodology of testing, the strength values obtained are subject to change.

References

1. Arundati R., Patil N.P. An investigation into the transverse and impact strength of a new indigenous high-impact denture base resin, DPI-TUFF and its comparison with most commonly used two denture base resins. The Journal of Indian Prosthodontic Society 2006; 6(3) : 133-138.

2. Woelfel JB, Paffenranger GC and Sweeney WT. Some physical properties of organic denture base materials. J Am Dent Asso 1963; 67 : 489-504.

3. Stafford G.D., Bates J.F., Huggett R., Handley R.W. A review of the properties of some denture base polymers. Journal of Dentistry 1980; 8(4) : 292-306.

4. Kanie T., Fujii K., Arikawa H., Inoue K. Flexural properties and impact strength of denture base polymer reinforced with woven glass fibers. Dental Materials 2000; 16(2) : 150-8.

5. Dagar S.R., Pakhan A.J., Thombare R.U., Motwani B.K. The evaluation of flexural strength and impact strength of heat-polymerized polymethylmethacrylate denture base resin reinforced with glass and nylon fibers: An in vitro study. The Journal of Indian Prosthodontic Society 2008; 8(2) : 98-104.

6. Yunus N., Rashid A.A., Azmi L.L. and Abu-Hassan M.I. Some flexural properties of a nylon denture base polymer. Journal of Oral Rehabilitation 2005; 32 : 65-71.

7. Chitchumnong P, Brooks S.C., Stafford G.D. Comparison of three- and four-point flexural strength testing of denture-base polymers. Dental Materials 1989; 5 : 2-6.

8. Zappini G, Kammann A, Wachter W. Comparision of tfacture test of denture base material. J Prosthet Dent 2003; 90: 578-85.

9. American Dental Association, Reaffirmed 1999: Revised American Dental Association Specification No.12 for denture base polymers. J Am Dent Assoc 1975; 90 : 451-58.

10. Standard test methods for impact resistance of plastics and electrical insulating materials. American Standards for testing materials, ASTM D256-88; 1988 : 57-73.

11. Hanna E.A., Shah F. K. and Gebreel A.A. Effect of joint surface contours on the transverse and impact strength of denture base resin repaired by various methods. An in vitro study. Journal of American Science 2010; 6(9) : 115-125.

12. Radzi Z., Abu Kasim N.H., Yahya N.A., Gan S.N., Daud N.M., Saffai L., Fadhel F.A. Impact strength of an experimental polyurethane-based polymer. Annals of Dentistry, University of Malaya 2007; 14 : 46-51.

13. Puri G., Berzins D.W., Dhuru V.B., Raj P.A., Rambhia S.K., Dhir G., Dentino A.R. effect of phosphate group addition on the properties of denture base resins. J Prosthet Dent 2008; 100(4) : 302-308

14. Jagger D.C., Jagger R.G., Allen S.M., Harrison A. An investigation into the transverse and impact strength of ‘high strength’ denture base acrylic resins. Journal of Oral Rehabilitation 2002; 29(3) : 263-267.

15. Jagger DC, Harrison A, Jandt K.D. The reinforcement of dentures. J Oral Rehabilitation 1999; 26(3) : 185-194.

16. Mac Gregor A.R. and Graham J., Stafford G.D. and Huggett R. Recent experiences with denture polymers. Journal of Dentistry 1984; 12(2) : 146-157.

17. Matthews E, Smith D.C. Nylon as a denture base material. Br Dent J 1955; 98(7) : 231-7.

18. Watt D.M. Clinical assessment of nylon as a partial denture base material. Br. Dent J 1955; 98(7) : 238-41.

19. Munns D. Nylon as a denture base material. The Dent Prac Dent Rec 1962; 13(4) : 142-6.

|